What Makes PIVOT's Power Rack Unique – Feature Guide

Share

Origins

The original idea for PIVOT didn’t have a Power Rack. The first version that solved my own exercise problem was similar to our old 'Lite' model, which had a pull-up bar, dip-bars, and emphasised opening-up underused bedroom space to use as a dedicated workout zone – while remaining a comfortable guest bedroom when needed.

It didn’t take long for the Power Rack idea to materialise, though, and right from the start it has been included in about 85% of our customer orders. That being said, it was a challenge to come up with something this good.

Challenges

There are lots of generic folding racks on the market designed to fit onto a wall, so would they work? Can you add any folding rack to PIVOT? The answer is a resounding no.

This isn’t about us creating a closed ecosystem where our accessories can only be used with our own-branded products (like some well-known brands!). It’s actually a much more complex design challenge than you may think, and as a result there is a lot of additional manufacturing cost in our rack.

Allowing it to pivot under the bed

If we bolted a generic folding rack to the underside of the bed, it would make lowering PIVOT into its horizontal bed mode virtually impossible because the feet of the power rack would hit the floor every time, even in the stored position, close to the bed frame.

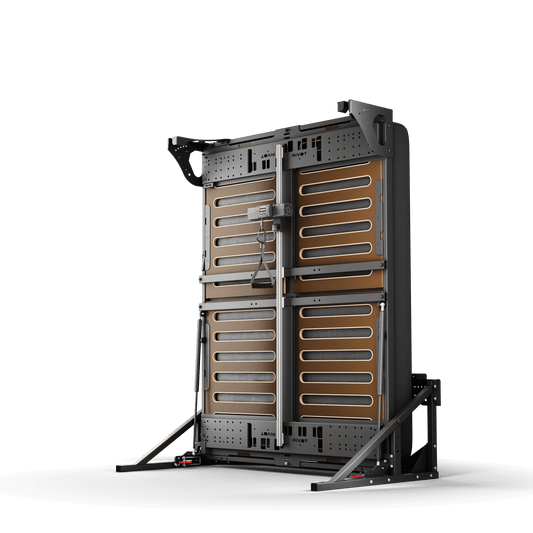

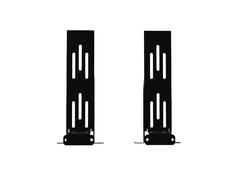

The PIVOT Power Rack in its closed position

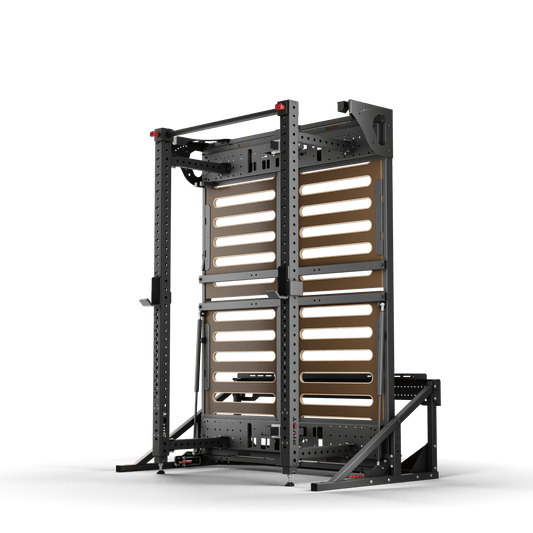

The PIVOT Power Rack in its Open Position with the telescopic feet pushed down into the floor for a strong and stable contact.

Our solution to the above problem has been to design telescopic feet in each upright that not only push down hard into the floor using strong levers, but also hold the feet up for storage through the use of a spring-loaded mechanism. This enables us to store weight plates on the folding rack arms, using an optional accessory, because unlike other folding racks the feet don't have to be scraped across the floor to open and close it. To finish it off, and to tackle the issue of potentially uneven floors, we add swivelling, adjustable feet with a high-grip rubber base.

Without this design, the rack uprights wouldn’t have a solid connection to the floor, causing them to move across the floor, as well as inhibit the use of any substantial weight on the rack arms. No one wants an unstable rack.

Weight challenges when the bed and rack are horizontal

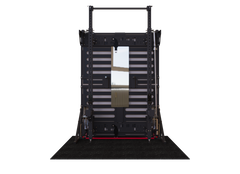

Most folding power racks simply have a pull-pin close to the hinge of each arm, and it’s enough to stop it from swinging out when not in use. When you have to deal with the rack being switched into a horizontal position, the forces on that hinge and pin are going to become too much – things would bend and ultimately break. The PIVOT Power Rack not only deals with this, but also enables you to store your weight plates on the rack, so it has to deal with this, too. We use two very strong poly-webbing straps, custom made for us with a heavy-duty clamping buckle – the more force is applied to try to pull the strap apart, the tighter the buckle grips the strap, and it’s rated to securely hold many times more weight than needed.

Dealing with the lack of available height

Virtually all power racks, even the folding variety, are considerably higher than the length of a traditional bed. Bolt a generic rack to the underside of a bed and you’ll have the uprights sticking out of the end of your bed a considerable distance. Our rack matches the length/height of your chosen bed, so nothing protrudes, but you get the maximum upright height for each bed length.

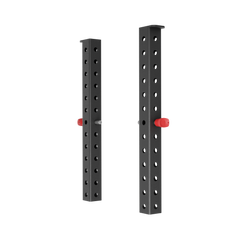

If your ceiling is high and you’d like a higher pull-up bar, we offer an Extension accessory, which can add over 400mm (16”) of height to your pull-up bar. Why don't we include it by default? So few customer homes have ceilings which can take advantage of this height, and the manufacturing cost is substantial so it's not something we could add for 'free'. We don't want any customer to have to pay for something they can't use.

Overall Complexity

A generic, wall-mounted power rack consists of around 60 components – screws included. Our rack includes 189 separate components and requires a huge amount of additional manufacturing. To ensure the telescopic parts at the top and bottom slide effortlessly in and out of the uprights, we bond low-friction plastic strips onto the inner parts using a powerful structural adhesive. To ensure your rack lasts a lifetime and doesn’t make annoying sounds, the swingarms pivot on self-lubricating bushes.

You may wonder if the additional complexity reduces the strength of the rack. Undeniably it does, but the weakest component in each rack upright has been rated to over one metric tonne! That’s 2,205 lbs. Per upright. That includes a safety factor of x2.5, so if you’re planning on racking 5 metric tonnes on your PIVOT Power Rack’s twin uprights, you should probably get in touch – we’ll sponsor you as you’d be lifting about ten times more than any person in history! If you’re not reaching those records then we’re quietly confident.

Is it stable and secure?

We've had a lot of people use a PIVOT Power Rack, and I can't remember a single one who didn't comment on how stable and sturdy it is. That seems to be what's on their mind – can a rack on a bed really be sturdy and secure? It can, and it is. Our bed is much stronger than most timber walls, which is what most folding racks are attached to. We use tighter manufacturing tolerances than normal, and that prevents movement between parts. The lever mechanism detailed above means that we are unique in how grounded and connected to the floor our rack is. PIVOT Bed is a heavy product, especially when you add a mattress, some stored weight plates and perhaps a barbell (which can be clamped to the bottom of the bed using our optional storage solution). We stipulate that the PIVOT Bed must be attached securely and structurally to either the wall behind the head of the bed or screwed into the floor, but this is due to the physics of how weight transfers during the pivoting motion. It has little to nothing to do with the stability of the product when vertical, though it does further improve the stability.

You've safety tested it, right?

Well yes, of course we have. When we were early in the product development phase, I was appalled to find that safety testing in this industry is, believe it or not, self-certification. Companies can literally just tell you they have tested their equipment, with nothing to back it up. Think for a second about what that means for all the ridiculously cheap equipment you keep eyeing up on Amazon. Is any of it safety tested? I have my own views.

We test to BS EN ISO 20957-1 Stationary Training Equipment – General Safety Requirements and Test Methods, which is a globally recognised, British Standard. It's widely misunderstood, with many brands failing to understand important concepts like 'safety factor' and therefore quoting misleading figures. As an example, brands often quote 'rated maximum' figures which are clearly actually the maximum weight which can be used before the equipment fails, potentially catastrophically. There is no safety margin in that and there must be a considerable margin built in to all quoted figures. The safety factor is x2.5 for the British Standard, and brands generally can't make their budget products handle a useful amount of weight safely if they quote their rated maximum figures correctly. So they choose to quote the absolute failure point which puts their customers in danger. "It says 200 KG max so I'll be okay with 210 KG", but the equipment may not even handle 200 KG due to manufacturing tolerance differences, issues with poor welds, etc. When we quote a maximum load figure, you can trust that we have tested it to x2.5 that figure. An example is our pull-up bar, which we rate to 130 KG. We've tested it to 325 KG and it passes the test easily, so you know you have a huge margin for error. If you're performing pull-ups with 325 KG / 717 LBS then we need to talk!

We’ve also tested our pull-up bars and dip-bars dynamically, simulating 12,000 exercises using our custom-designed, computer-controlled test rig. This is not the maximum number of repetitions we warranty the rack for – that’s infinite reps over 25 years – it’s just the number demanded by the British Safety Standard.

All power racks are not equal.